For other languages:

For other languages:

In this course you will learn more about the student is introduced to the milestone activities associated with planning for and executing a well construction programme. They will also discover in more detail the roles and responsibilities of core personnel required to plan and execute a well. Click to continue>>

This course discusses the causes of a kick, methods of kick detection, well control procedures, and the components and function of surface and subsea well control equipment. Also covered are Operational Pressures and will give students a good understanding of the pressure relationships in the wellbore and rock formation. Continue>>.

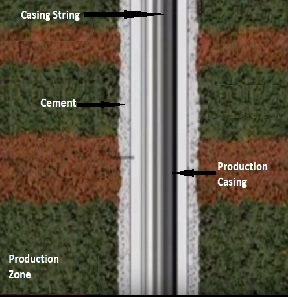

This course is designed for use by students to gain an understanding of the principles behind the use of casing within the wellbore and the factors involved in casing string design. Also covered are the functions of oilwell cement, the API classification and properties of dry cement and neat slurry and the effect of additives on these properties. Continue>>.

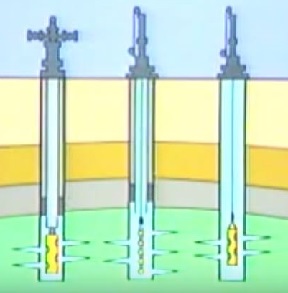

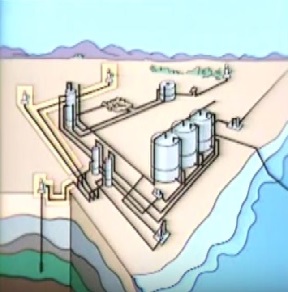

In this course you will learn more about the process of converting a drilled wellbore into a production or injection system. The interface between the reservoir and surface production. The resulting system should establish a safe and efficient connection between the reservoir, the wellbore up to surface so that hydrocarbons can be produced. Continue>>.

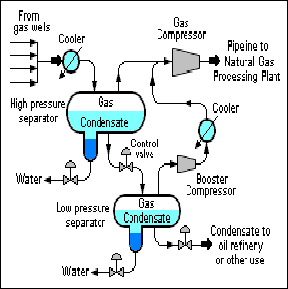

Before we use formation fluid in cars, busses, plane, heating, ship and other machinery, it have to undergo extensive treatment. In this course you will be enligthen on the processes and stages invloved. Processes like 3-Phase Horizontal Separator, Vertical Heater -Treater and Skim Pile for Water Discharge. Continue>>

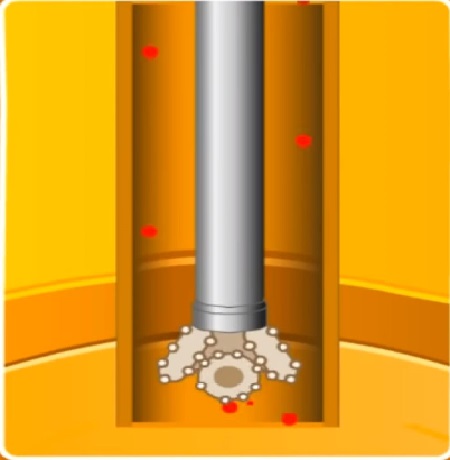

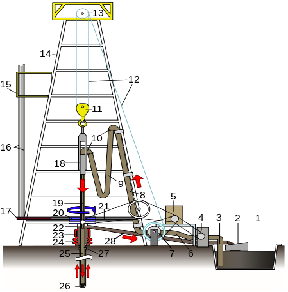

This topic is designed for use by students to gain an overall appreciation of the general components of a drilling rig and the equipment utilised during drilling. A drilling rig essentially comprises a derrick, the draw-works with its drilling line, crown block and travelling block, and a drilling fluid circulation system including the standpipe, rotary hose, drilling fluid pits and pumps. Continue>>.

Crude oil when transported will normally have a Reid Vapour Pressure of between 1 and 12 psia, depending on its origin, the processing it has undergone and the degree of ‘weathering’, which has occurred. It is possible to pump most United Kingdom (UK) North Sea crude at ambient temperature, but some of the recent Eocene developments will yield a crude that will need treatment for economic pumping. Continue>>.

Like any other engineering task, the design of a pipeline needs to be tackled systematically. Figure 1 is a route map through this systematic process. This systematic process is rarely a straightforward sequence of operations; usually the design process requires that a series of loops be performed due to the complex interactions between the different factors inherent in the design process. Continue>>.

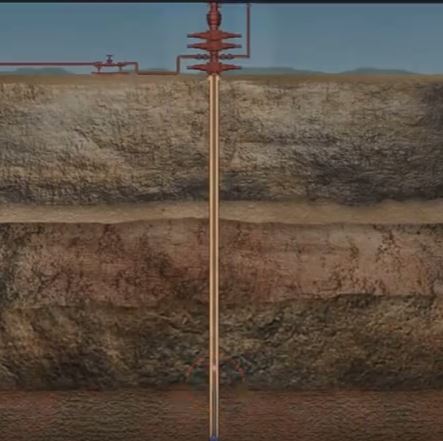

In this topic the student is introduced to the milestone activities associated with planning for and executing a well construction programme. They will also discover in more detail the roles and responsibilities of core personnel required to plan and execute a well. Different organisational structures to deliver a well are also discussed. In addition, the student learns about generic objectives for a well and what specific information is required to allow comprehensive well planning.

In this topic the student is introduced to the milestone activities associated with planning for and executing a well construction programme. They will also discover in more detail the roles and responsibilities of core personnel required to plan and execute a well. Different organisational structures to deliver a well are also discussed. In addition, the student learns about generic objectives for a well and what specific information is required to allow comprehensive well planning.

In this topic the student is introduced to the milestone activities associated with planning for and executing a well construction programme. They will also discover in more detail the roles and responsibilities of core personnel required to plan and execute a well. Different organisational structures to deliver a well are also discussed. In addition, the student learns about generic objectives for a well and what specific information is required to allow comprehensive well planning.

In this topic the student is introduced to the milestone activities associated with planning for and executing a well construction programme. They will also discover in more detail the roles and responsibilities of core personnel required to plan and execute a well. Different organisational structures to deliver a well are also discussed. In addition, the student learns about generic objectives for a well and what specific information is required to allow comprehensive well planning.